Choose products with high demand and low competition to maximize your selling potential. Use tools like Jungle Scout or Helium 10 to analyze sales volume, profit margins, and customer reviews before investing. Prioritize items that fit well in standard-size warehouses to reduce storage fees.

Sending inventory directly to Amazon’s distribution centers eliminates the need for personal warehousing. This allows you to focus on marketing and scaling sales while Amazon handles packing and shipping. Efficient stock management ensures your products stay in stock without incurring excessive long-term storage costs.

Selling through this platform benefits from Prime eligibility, which boosts visibility and conversion rates. Automated order processing reduces manual work, accelerating delivery times and improving customer satisfaction. Calculating all fees upfront–including referral, fulfillment, and storage charges–helps maintain a healthy profit margin.

Profit optimization comes from balancing product cost, shipping expenses, and pricing strategy. Leveraging Amazon’s global network can expand reach without extra logistics hassle. Regularly reviewing performance metrics enables timely adjustments in inventory levels and advertising spend for sustainable growth.

Amazon FBA: fulfillment business model

Maximizing profit through efficient product distribution requires understanding the core mechanism behind inventory handling and order processing in online retail. The Amazon system enables sellers to store items in centralized warehouses, where the platform takes responsibility for packaging, shipping, and customer service. This approach significantly reduces operational workload for vendors focused on selling diverse products.

Leveraging this sales strategy involves selecting high-demand goods with favorable margins while maintaining control over supply chain logistics. By entrusting storage and dispatch tasks to a specialized network, sellers can concentrate on market research, product sourcing, and scaling their commercial activities without being bogged down by daily fulfillment complexities.

Technical Breakdown of the Distribution Approach

The fulfillment infrastructure operates on an integrated framework combining warehouse management software (WMS), automated sorting systems, and real-time tracking technologies. Once a seller’s inventory arrives at the designated facility, it is cataloged and stored based on size, category, and turnover rate. When an order is placed, algorithms prioritize picking routes to optimize speed and minimize errors.

This streamlined procedure ensures that customers receive packages swiftly while reducing overhead costs related to manual labor and storage inefficiencies. Sellers benefit from detailed analytics dashboards providing insights into stock levels, shipment timelines, and return rates–all crucial for refining product offerings to increase profitability.

For example, a vendor specializing in electronic accessories might notice certain items moving faster due to seasonal demand or promotional campaigns. Using this data, they can adjust restocking quantities accordingly or experiment with bundling strategies that enhance average transaction values without increasing logistical burdens.

- Storage fees: Monthly charges based on volume occupied in warehouses.

- Fulfillment fees: Costs per unit covering picking, packing, and shipping operations.

- Long-term storage surcharges: Applied to slow-moving inventory after extended periods.

Understanding these components helps sellers maintain profitable pricing models while avoiding unexpected expenses linked to excess stock or inefficient turnover cycles.

Sellers aiming for sustainable income streams should continuously analyze sales metrics alongside external factors such as competitor pricing and seasonal trends. Combining accurate forecasting with responsive inventory management enables consistent product availability without tying up excessive capital in unsold merchandise–a common pitfall in online retail ventures utilizing third-party logistics frameworks.

How to source profitable products for selling through a fulfillment warehouse

Finding profitable items for your sales operation starts with detailed market research focused on demand, competition, and margin analysis. Use data tools that provide real-time insights into product rankings, customer reviews, and price fluctuations. These metrics help identify opportunities where supply lags behind demand or where improvements in quality can justify higher pricing and thus greater profit.

Another effective strategy is analyzing inventory turnover rates at warehouses specializing in order processing. Fast-moving products reduce storage fees and risk of obsolescence, directly impacting net earnings. Incorporating seasonality trends into your sourcing decisions allows adjustments for peak sales periods without overstocking during slow months.

Technical approaches to product selection

Employing keyword research tools reveals search volumes linked to specific goods, helping prioritize items with proven interest. Combining this with competitor analysis uncovers gaps or niches underserved by existing sellers. For example, if multiple vendors offer generic kitchen gadgets but few provide eco-friendly alternatives, the latter could yield better margins due to less saturated competition.

Cost structure evaluation involves calculating landed costs–including manufacturing, shipping to fulfillment centers, customs duties, and warehouse handling fees–and comparing these against typical sale prices on major online platforms. Products with at least a 30-40% gross margin after all expenses are generally considered viable for sustained profitability.

- Identify suppliers capable of consistent quality and reliable delivery times;

- Validate product compliance with safety regulations relevant to target markets;

- Assess packaging suitability for automated sorting and storage systems in warehouses.

A practical case study is an electronics seller who integrated barcode tracking systems within their supply chain. This minimized errors during stocking and shipment stages while optimizing space utilization at distribution hubs. The result was increased sell-through speed alongside reduced warehouse overheads.

Finally, test small batches before committing significant capital to large inventories. Pilot runs enable monitoring actual consumer response and operational challenges within the logistics network. Adjustments based on this feedback loop improve stock forecasting accuracy and protect profit margins from unexpected disruptions in supply or demand dynamics.

Setting up your seller account for streamlined product distribution

To begin selling efficiently through the platform, register an account specifically designed for merchants. This process requires providing detailed personal or company information, including tax identification and bank details to enable seamless financial transactions. Selecting the appropriate account type–individual or professional–depends on expected sales volume; professionals benefit from reduced fees per item when selling over 40 units monthly.

After registration, configuring inventory management is essential. Upload product listings with accurate descriptions, pricing, and stock quantities to ensure real-time synchronization with storage facilities. Utilizing integrated shipping centers reduces logistical overhead by allowing direct dispatch of items from suppliers to warehouses, optimizing delivery times and minimizing handling costs.

Optimizing warehouse integration and maximizing returns

Leveraging centralized storage hubs allows sellers to store goods closer to end customers, improving delivery speed while decreasing operational complexity. This approach supports bulk shipping from manufacturers directly into fulfillment centers, where orders are picked and dispatched upon purchase. Monitoring stock levels through dashboard analytics helps prevent overselling and identifies best-performing products contributing most significantly to revenue.

Profitability hinges on balancing fees associated with storage space and order processing against competitive pricing strategies. For example, seasonal demand fluctuations require dynamic inventory adjustments to avoid excess warehousing charges. Employing automated tools that analyze sales trends enables data-driven decisions about restocking frequency and quantity, ensuring consistent availability without unnecessary expenditure.

Creating Optimized Product Listings

Start by crafting product titles that include precise keywords related to the item’s main features and category. This technique improves visibility in search algorithms used by the selling platform, directly influencing customer discovery. For example, a listing for wireless earbuds should incorporate terms like “Bluetooth,” “noise-cancelling,” and “long battery life” to target relevant queries effectively.

Descriptions must combine technical specifications with clear benefits, addressing potential buyer questions upfront. Use bullet points to highlight key attributes such as dimensions, materials, compatibility, and warranty information. A well-structured description reduces return rates by setting accurate expectations and supports higher profit margins through increased conversion rates.

Leveraging Images and Multimedia

High-resolution images showcasing multiple angles of the product enhance buyer confidence and reduce hesitation during purchase. Incorporate lifestyle photos demonstrating real-world use cases alongside close-ups of critical details. Including videos that explain setup or unique features can further differentiate your offerings from competitors stored in third-party warehouses.

Technical data shows listings with at least five images have a 35% higher conversion rate compared to those with fewer visuals. Additionally, embedding infographics highlighting product advantages simplifies complex information for new customers unfamiliar with certain technologies or applications.

Inventory Integration and Pricing Strategies

Synchronize inventory levels accurately between fulfillment centers and online listings to prevent overselling or stockouts, which harm seller ratings and profitability. Dynamic pricing tools can adjust costs based on demand fluctuations, competitor actions, or seasonal trends without manual intervention.

- Implement automated alerts for low stock thresholds.

- Use historical sales data to forecast replenishment timing.

- Apply tiered pricing models for bulk purchases to incentivize larger orders while maintaining healthy margins.

Customer Feedback and SEO Optimization

Encouraging verified purchasers to leave detailed reviews increases listing credibility and influences algorithm ranking positively. Analyze recurring themes in feedback to update listings with clarifications or additional imagery addressing common concerns. Search engine optimization within the platform requires periodic keyword research updates since competitive terms evolve as new products enter the marketplace.

The synergy of these elements–precise textual content, rich media assets, smart inventory management, adaptive pricing strategies, and active reputation building–results in optimized product listings that maximize revenue streams within a distributed logistics framework. Applying these recommendations will increase visibility, improve customer satisfaction, and ultimately elevate profit outcomes through efficient selling operations supported by external warehouse networks.

Managing Inventory and Shipping Costs in the Selling Process

Optimizing stock levels is key to reducing expenses related to storage facilities while maintaining product availability for customers. Holding excessive units in a warehouse increases monthly fees and risks long-term storage surcharges, which can significantly erode profit margins. Employing demand forecasting tools that analyze sales velocity and seasonal trends helps sellers maintain balanced inventory and avoid overstocking or stockouts.

Shipping fees directly impact net revenue, especially when using centralized distribution centers. Choosing the right parcel size and packaging materials reduces dimensional weight charges imposed by carriers. For example, consolidating multiple small items into one shipment lowers per-unit transport costs. Additionally, integrating automated shipping software with carrier APIs streamlines label creation and tracking, minimizing human errors and delays.

Practical Strategies for Cost Control

Sellers utilizing third-party logistics services benefit from understanding their fee structures thoroughly. Storage costs are often tiered by volume or duration; therefore, rotating slow-moving products out of fulfillment locations can prevent penalties. Implementing periodic inventory audits supports accurate stock records, preventing discrepancies that lead to unexpected replenishment or returns.

Another approach involves analyzing historical performance data to identify best-selling SKUs versus low-demand items. Prioritizing fast-moving goods in high-turnover warehouses accelerates order processing times and reduces holding costs. For instance, some merchants split inventory between regional centers closer to target markets, cutting transit time and freight expenses.

Effective cost management requires continuous monitoring of both warehousing fees and shipping tariffs. Leveraging dashboards that display real-time metrics allows quick adjustments–whether reallocating stock or negotiating better carrier rates based on volume commitments. Such data-driven decision-making enhances operational efficiency while safeguarding profitability across all stages of the seller’s supply chain.

Scaling FBA with Advertising Strategies: A Technical Conclusion

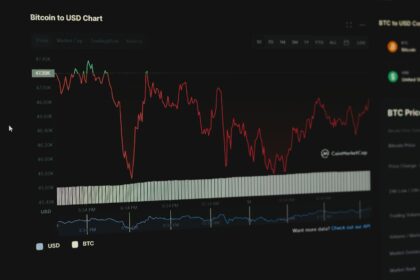

Prioritize targeted ad campaigns focused on high-conversion keywords to maximize the return on investment when selling inventory through a centralized warehouse system. Leveraging pay-per-click and sponsored product ads enables precise demand forecasting, reducing storage fees and optimizing stock turnover rates for improved profit margins.

Integrating dynamic bidding algorithms with real-time sales data can refine promotional spend, ensuring funds are allocated to products demonstrating the highest velocity. This approach supports scalable operations by aligning marketing efforts with inventory availability and logistical throughput capacities.

Key Takeaways and Future Directions

- Data-driven advertising: Utilize machine learning models to analyze customer behavior patterns, enabling personalized product promotion that elevates conversion without inflating acquisition costs.

- Inventory synchronization: Maintain tight coupling between promotional activities and warehouse stock levels to prevent overstocking or stockouts, which directly impact profitability.

- Automation tools: Deploy automated campaign management platforms capable of adjusting bids and budgets based on fulfillment center constraints and sales velocity metrics.

- Cross-channel integration: Expand beyond platform-native ads by incorporating external traffic sources that feed into the same fulfillment pipeline, enhancing overall reach without compromising logistic efficiency.

The ongoing evolution of digital advertising technologies combined with advanced inventory management systems will redefine how sellers scale their operations within distributed warehousing networks. By harnessing predictive analytics alongside adaptive marketing strategies, sellers can anticipate demand spikes and optimize allocation across multiple storage locations, ultimately driving sustainable growth in profits while maintaining operational agility.

This strategic alignment between promotional tactics and physical distribution infrastructures represents a critical frontier for those aiming to scale product sales efficiently without sacrificing cost control or delivery speed. As algorithmic capabilities improve, expect greater automation in balancing ad spend against fulfillment capacity–facilitating smarter expansion pathways grounded in measurable performance data.